Continuous powder coating and decorating line for coil :

Aluminum or steel coil is fed in as a raw material coil sheet, and be finished as a decorated coil. Using the latest surface pre-treatment technology, a 60-80µm powder coating layer enables the coil to accept sublimation, allowing it to be used for a wide variety of applications such as doors, building decoration panels, ceiling decorations, whereas liquid coating coils have limited applications.

The coil coating line is for thin sheet, functions include automatic de-coil, pre-treatment, powder coating, curing, continuous transfer printing, automatic rewinding.

Coil coating line enables production automation, powder coating and transfer printing automation, is a breakthrough in regards to environmental protection, labour and production cost, and brings the chance for big business for thin steel sheet manufacturers, distributors, and metal door manufacturers, and broadens the possibilities for new product and market development.

Technology Advantages :

Pollution-free zero emissions:No any pollution components in the processing of the whole production. Gas, liquid and solid are zero emissions.

Small footprint .one standard door plank product line with the capacity of 2000 sets/day, theoretical number of production area is 600㎡,actual area (height of Tunnel plane :6m)is only 200㎡.

Small need labor: only 10 persons for one line one standard door plank product line with the capacity of 2000 sets/day.

Automatic production: production line with full-automatic surface pretreatment ,spray, Transfer printing is applied from more than 10 innovation technology of Sanle, this machine lays the foundation of producing plate firstly, door crafts later. It makes mechanization and automation achieved for metal doors.

High coating quality: automatic Pre-treatment---Automatic spray-- Powder melting, leveling and curing under precision process condition—transfer in complete penetration—automatic cover the protective film. The whole process confirms that color painting effect is much better than PVC and manual transfer effect obviously. Its weather ability could be lasted more than 15 years, and the internal quality target of the products the machine made is over national standard.

Low energy consumption: only one time for heating during whole production process, install all line, equipped with reasonable scientific.

Low operating cost: full capacity, product cost for complete transfer printed steel is about US$1(not included packaging protective film).the cost is 50% for average of domestic big manual transfer coating enterprises.

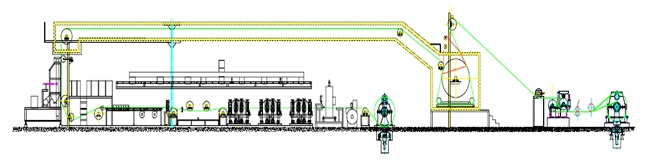

Coil coating line layout

Coil loading.... ---> coil decoiling ... ---> degreasing..... ---> rinsing and etching... --->

Passivating... ---> Drying... ---> Powder coating.... ---> powder curing.... --->

continuous transfer printing.... ---> automatic winding.... ---> unloading.

Consists of coil coating line :

Decoiler

Coil connecting equipment

Pretreatment system

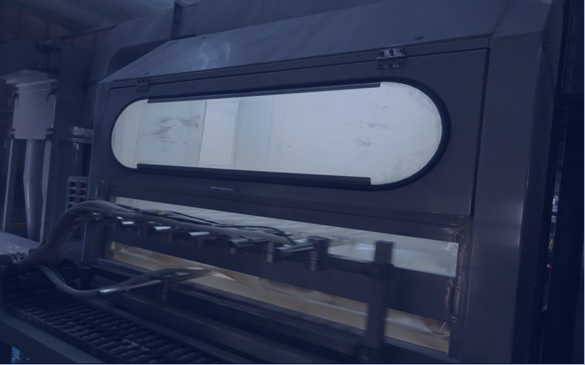

Automatic powder coating system

Powder curing oven and heating system

Continuous transfer printing system

Cooling and film covering system and rewinding system

Monitor and center control system

Technical Specifications :

Overall equipment size :

Length: 150—170m,width: 3m,

Height of workshop: more than 6.5m.

Height of equipment: 4m .

Cover area of whole line: around 200㎡.

Crucial Components :

1. transducer:Mitsubishi & Panasonic

2. PLC: Mitsubishi & Siemens

3. touch screen: Mitsubishi & Siemens

4. electrostatic spray gun:Aben (Japan) & WAGENA(Germany)

5. some materials and electric

appliance : Germany & Japan

6. other parts, material and component: national standard & famous national brand.